Selecting the right gauge extension cord gauge guide for power tools is crucial for ensuring both the performance of your tools and your safety.

The wire gauge of an extension cord refers to the thickness of the wire inside, which dictates its capacity to carry current without overheating. Understanding this and matching it to the power requirements of your tools is key to preventing damage to your equipment and potential safety hazards.

Using an incorrect gauge can lead to insufficient power delivery. This reduces the efficiency of power tools and increases the risk of overheating or fire hazards.

Therefore, it is essential to identify your power tool’s amperage requirements and select an extension cord that can handle the current without causing voltage drops or overheating.

This introduction will pave the way for a more in-depth look at how to accurately match extension cords to the diverse needs of your power tools.

Covering everything from the extension cord gauge guide to the extension cord amp rating, including cord length and safety considerations.

Understanding Extension Cord Gauge and Its Importance

Understanding the wire gauge of an extension cord is pivotal for the safety and efficiency of power tools.

The gauge, denoted by American Wire Gauge, measures the thickness of the wire within the cord.

Here’s a simple breakdown that illustrates the importance of the AWG rating:

Lower AWG number = Thicker wire

A lower wire gauge number signifies a thicker wire, capable of carrying more current without overheating.

This is crucial for power tools that draw a significant amount of power, ensuring they operate at their best.

Amperage and Gauge Relationship

The thickness of the wire directly influences its amperage load capacity.

Essentially, thicker wires with the appropriate wire gauge can handle a higher amperage, ensuring that power tools operate efficiently without the risk of overheating or fire hazards.

To match the gauge of an extension cord with the power requirements of your tools, consider the following guide and be mindful of cord lengths:

Identify Power Tool Requirements

Check the amperage requirement of your power tools.

This information is typically found on the tool itself or in the user manual, and is a critical part of this guide, ensuring you match the motor specs accurately.

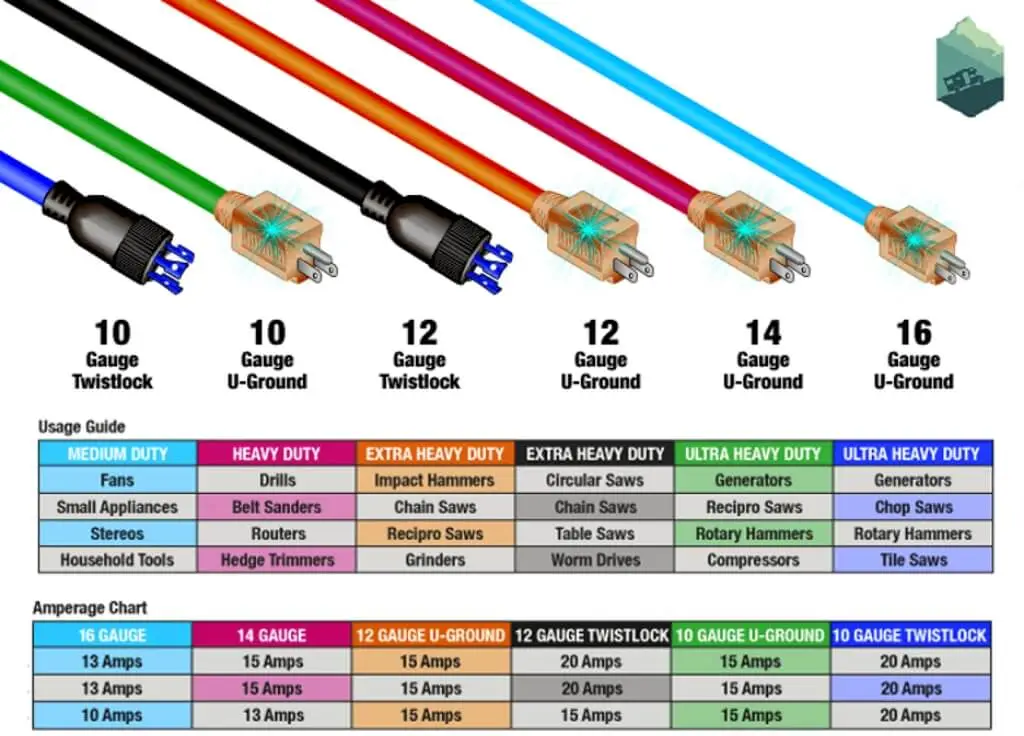

Select the Correct Gauge

Consult an extension cord gauge chart to pair your tool’s amperage with the correct extension cord gauge.

For example, a 14-gauge extension cord is well-suited for tools that operate up to 15 amps, making it an ideal choice for medium-duty tasks.

Extension Cord Gauge Guide:

- 16-gauge: For light-duty extension cords, which cater to items like lamps and small appliances drawing up to 10 amps, the cord size should not exceed 50 feet to maintain efficiency and safety.

- 14-gauge: Medium-duty applications, such as operating power tools and small appliances that require up to 15 amps, are best served by extension cord lengths that do not surpass 100 feet to ensure reliable power delivery.

- 12-gauge: Heavy-duty tasks demand robust solutions; therefore, using an extra heavy-duty extension cord for large power tools and appliances up to 20 amps is recommended, with a cord size that can extend up to 150 feet.

- 10-gauge: For the most demanding applications involving industrial equipment and machinery, an extra heavy-duty extension cord capable of handling up to 30 amps is advisable, with cord sizes reaching up to 250 feet for optimal performance.

Utilizing an extension cord with a gauge too thin can lead to hazardous conditions, such as overheating and fires.

The cord lengths also influence performance, with longer cords introducing more electrical resistance and potential voltage drops.

To ensure maximum efficiency and safety, select the shortest cord necessary for your work, as advised by this guide.

In conclusion, choosing the right gauge for your extension cord is not solely about enhancing tool efficiency; it’s a vital safety precaution.

Aligning your tool’s amperage with the appropriate gauge and mindful cord length selection contributes to a higher safety scoreboard and guarantees secure, efficient operation.

Identifying Your Power Tool’s Requirements

Identifying your power tools’ energy needs is paramount for efficient and safe operation.

This crucial step involves understanding the motor specs to ensure your tools perform optimally.

Here’s a method to accurately determine the amperage requirements of your power tools:

Check the Tool’s Nameplate:

- Look for the nameplate on the tool’s body or motor housing.

- The nameplate typically lists the tool’s amperage (amps) requirement.

Tool Amperage Guide:

- Small power tools like sanders and jigsaws need 2 to 8 amps. Heavier equipment, such as routers and saws, typically draw 6 to 16 amps.

- Specialized tools have their specific amperage requirements:

- Oscillating Multi-Tool: 2-4 amps

- Drills: 6-10 amps

- Sanders: 2-10 amps

- Grinders: 7-15 amps

- Rotary Hammers: 10-15 amps

- Circular Saw: 13-15 amps

- Routers: 13-15 amps

- Core Drills: 15-20 amps

Electrical Service Consideration:

- Contemporary residences, constructed within the past 40 years, are usually equipped with an electrical supply ranging from 100 to 200 amps, which is adequate for operating both household appliances and power tools while maintaining electrical safety.

- Dwellings erected before 1950 that possess a 60-amp service might necessitate an electrical upgrade to enhance electrical safety and prevent circuit breakers from tripping when utilizing power tools.

Upon ascertaining the amperage needs, it’s essential to pair these with the correct gauge of the extension cord as per the extension cord gauge guide.

The aim is to select a cord that can manage the power tools’ current and voltage demands without causing voltage drops or overheating.

Always consult the tool’s user manual or adhere to the manufacturer’s specs, particularly for tools that need 220V 20A.

For safety and peak performance, check the prongs for damage before use, and ensure power tools are operated away from any hazardous conditions.

Selecting the Right Extension Cord Gauge

Choosing the right gauge for an extension cord is a critical step to guarantee the safety and efficiency of your power tools.

The wire gauge within the extension cord dictates the current it can carry without risk. Employing a cord that’s too thin can result in overheating, tool damage, or even fire hazards.

Here’s a guide to aligning the extension cord gauge with the power demands of various tools:

Small Appliances (Up to 13 Amps):

16-gauge cord: For devices drawing up to 13 amps, such as lamps or small power tools, selecting extension cord lengths and cord size suitable for the task is crucial. For optimal safety and performance, cords ideal for short distances, up to 50 feet, should be used.

Larger Appliances (Up to 15 Amps):

14-gauge cord: Extension cords designed for appliances drawing up to 15 amps, such as refrigerators or medium-sized power tools, are safer and fall within recommended extension cord lengths. For optimal performance and safety, it’s advised to use these cords for distances up to 100 feet, ensuring the cord size is appropriate for the electrical load.

Heavy-Duty Tools (Up to 20 Amps):

12-gauge or 10-gauge cord: For power tools or appliances that require up to 20 amps, like shop vacuums or circular saws, it’s crucial to select the right extension cord lengths. A 12-gauge cord is suitable for up to 150 feet, while a 10-gauge cord can efficiently handle distances up to 250 feet, aligning with the recommended cord size for such equipment.

| Tool Amperage | Recommended Cord Gauge | Maximum Cord Length |

| Up to 13 Amps | 16 AWG | 50 Feet |

| Up to 15 Amps | 14 AWG | 100 Feet |

| Up to 20 Amps | 12 AWG or 10 AWG | 150 Feet (12 AWG) / 250 Feet (10 AWG) |

Key Considerations:

- Length Matters: It’s essential to note that with extension cord lengths, electrical resistance increases, potentially causing a voltage drop. To maintain the correct voltage rating, for every additional 100 feet of cord, it’s wise to step up one gauge size, thus compensating for the resistance and ensuring the safety and effectiveness of your electrical setup.

- Safety First: Selecting an extension cord with a gauge that’s suitable for the highest amperage your tools will draw is a key tip from any extension cord gauge guide. This practice ensures that your tools operate efficiently and safely, preventing the risk of wire gauge-related overheating.

- Voltage and Plug Styles: In addition to considering the gauge and length, it’s equally important to match the voltage requirements and plug types of your tools with the extension cord. This attention to detail regarding extension cord types ensures compatibility and safety in your electrical endeavors.

By following these expert guidelines and consulting the provided gauges of extension cords guide, you can confidently choose the appropriate gauge and extension cord lengths for your power tools. This careful selection promotes safety, efficiency, and the longevity of your valuable equipment.

Factors to Consider When Choosing an Extension Cord

Selecting the right extension cord for your power tools or electrical devices involves a careful consideration of several factors to ensure safety and efficiency. These factors include understanding the different extension cord types and knowing the specific types of extension cords that are best suited for your equipment’s needs.

Current Draw and Cord Rating:

- Be aware of the current draw of the device or power tool in use.

- It’s crucial to choose an extension cord that can handle the required load and length. For example, a power tool that draws 15 amps should be matched with an extension cord rating that can accommodate this demand, rather than a cord with an extension cord rating of only 10 amps.

- When shopping for extension cords, ensure the amp rating meets or exceeds your appliance’s needs. Adhering to recommended ratings is crucial.

Type and Durability:

- Selecting the incorrect type of extension cord, such as utilizing cords designed for outdoor use indoors, or the other way around, poses a significant risk. Understanding the different types of extension cords is crucial for electrical safety.

- Choosing heavy-duty extension cords is wise as they provide enhanced durability and versatility for various tasks, including those outdoors, aligning with the recommended extension cord types for such applications.

- To ensure both quality and electrical safety, look for extension cords that have been approved by independent testing laboratories, such as those that are UL-listed, or certified by Intertek (ETL) or the Canadian Standards Association (CSA).

Length, Plug Types, and Special Features:

- The performance of an extension cord is influenced by its length due to electrical resistance; therefore, opting for shorter extension cord lengths is advisable to reduce friction and maintain an optimal voltage rating.

- When considering plug types, it’s important to note that extension cords come with either 2-prong or 3-prong plugs. The latter includes a ground wire connection, offering an additional layer of electrical safety by decreasing the likelihood of electrical shock and fires.

- Incorporating special features such as a Ground Fault Circuit Interrupter (GFCI) and lighted plugs, alongside connector boxes or multiple sockets, can significantly boost your safety scoreboards while also adding convenience.

Maintenance and Care:

- To maximize extension cord care and enhance storage & organization, always keep cords flat and uncoiled during use, which helps prevent damage and prolongs their life.

- A regular inspection for damage is essential for electrical safety, and it’s crucial to ensure that cords are not bent, twisted, or excessively stretched to maintain a safe environment.

- Employing clamps, a vice, or other devices to securely hold the workpiece, along with ensuring all tools and cords are properly grounded or double-insulated, are key electrical safety measures that align with lockout tagout procedures.

By considering the appropriate extension cord types and adhering to recommended practices, users can ensure their power tools operate efficiently.

This would minimize the risk of damage or safety hazards that are often associated with the use of improper types of extension cords.

Dangers of Using an Incorrect Gauge

Understanding this guide is critical for electrical safety, as the dangers of using an incorrect gauge are multifaceted and can lead to severe consequences.

Overheating and Fire Hazards:

Overheating

Furthermore, utilizing an extension cord with an improper gauge can result in overheating due to the cord’s inability to handle the required electrical current.

This can lead to potential electrical safety hazards such as insulation melting or cord fires.

Fire

Utilizing an extension cord that is not suitable for the power tool’s current demand can lead to fire hazards. A direct result of the excessive heat from an overtaxed electrical system.

Consulting an extension cord gauge guide can prevent such risks by ensuring the cord’s capacity matches the tool’s requirements.

Damaging Voltage Drop

However, a cord that is too lengthy or thin can result in a significant voltage drop, which in turn can damage equipment and create fire hazards.

To maintain electrical safety, it’s crucial to use the appropriate cord to prevent voltage drops that could harm motors.

Physical Damage and Safety Risks:

Equipment Damage

Selecting the wrong gauge extension cord can cause power tools to fail prematurely due to insufficient voltage, posing risks to both the equipment and the user.

Adhering to this guide recommended by the equipment manufacturer can mitigate these dangers.

Injury Risk

Using indoor extension cords outdoors without proper shock protection can increase injury risks and degrade the cord over time, leading to electrical safety concerns.

Understanding the types of extension cords suitable for various environments is essential to prevent electric shock or fire hazards.

Improper Use and Alterations:

Overuse and Misuse

Consequently, overloading an electrical system can create safety hazards. Awareness of extension cord ratings and adherence to electrical safety guidelines are critical to prevent these risks.

Alteration Risks

Altering a three-prong extension cord by removing the grounding pin to fit a two-prong outlet jeopardizes electrical safety by increasing the risk of electric shocks.

It’s important to maintain the integrity of the cord’s safety features and avoid such modifications.

To ensure safety and equipment longevity, it’s vital to choose the correct gauge, as outlined in this guide.

Based on the power tool’s amperage and the required cord length. Regular inspection of cords for damage and timely replacement are key practices for safe operation.

Safety Tips and Best Practices

Adhering to essential extension cord safety tips and best practices is crucial for the safe and efficient use of extension cords with power tools.

These guidelines were created to avert accidents and guarantee that your power tools function at their peak efficiency.

Extension Cord Safety Basics:

- Correct Power Cord Type

- Avoid Overloading

- Proper Storage of Cords

- Do not use the Cord in Wet Conditions

Usage and Installation:

- Temporary Solution: Keep in mind that extension cords are intended for temporary use and are not a substitute for permanent wiring. If you’re consistently relying on extension cords, it’s wise to consider the installation of additional outlets to enhance electrical safety.

- One Appliance Per Cord: To uphold electrical safety and prevent overloading, it’s advisable to connect only one appliance to an extension cord at any given time, in line with extension cord ratings.

- Direct Plug-In: For optimal electrical safety, it’s advisable to plug appliances directly into mounted electrical receptacles, avoiding the hazard of chaining multiple cords together.

- Avoid Physical Alterations: To uphold electrical safety, never snake cords through doorways, ceilings, walls, or floors where they’re prone to damage, and resist the urge to remove the grounding pin for compatibility with various outlet types.

Maintenance and Inspection:

- Regular Checks: Conduct a regular inspection of the cord before each use, checking for fraying or cuts, and adhere to electrical safety by replacing any damaged cords without delay.

- Loose Connections: Ensure plugs fit securely into the electrical outlet to prevent poor connections that can lead to overheating, replacing any loose-fitting outlets to maintain electrical safety.

- Cord Tension: Maintain a bit of slack in flexible cords to reduce stress on electrical terminals, thus preventing damage and enhancing electrical safety.

- Safety Covers: Affix safety covers on unused receptacle outlets on extension cords to prevent accidental contact, a simple yet effective electrical safety measure.

Adhering to these safety tips and best practices can drastically lower the risk of accidents and extend the life of your tools.

Always prioritize safety by selecting the appropriate extension cord for the task and caring for it diligently.

Conclusion

Grasping the nuances of selecting the correct extension cord gauge is crucial for the safety and efficiency of your power tools.

It’s essential to match your tool’s power requirements with the appropriate cord gauge, a process this guide makes clear.

Utilizing cords with the right gauge ensures your power tools function without the dangers of overheating or potential fire hazards.

The inclusion of a handy reference table simplifies the selection process, making this guide a valuable resource for safeguarding your equipment and maintaining a secure work environment.

Leave a Reply